Introduction to the heavy plate/sheet crusher

Traditional crushers face certain difficulties in crushing plastics, profiles, and wood-plastic profile products. They usually require a relatively large crushing chamber to process recycled materials that are large in volume and quantity. The feed hopper of the heavy plate/sheet crusher, which is almost parallel to the ground, makes the feeding of longer materials extremely simple and convenient. Since the rotor of the machine can automatically grip the materials to be crushed, there will be no material blockage.

Features of The heavy plate/sheet crusher

1. High-Performance Cutting & Versatile Processing

Equipped with imported DC53 steel knives, the crusher easily handles both soft and hard plastics. Different cutters and screen apertures can be selected to suit various material types, ensuring efficient and customizable processing. Its sharp, durable blades make replacement simple and maintain consistent shredding performance over time.

2. Automated & Efficient Operation

The pneumatic lift system and automatic recovery system simplify feeding and collection, reducing manual labor and improving operational efficiency. The anti-blockage rotor prevents material jams, allowing continuous, smooth crushing and minimizing production interruptions.

3. Robust & User-Friendly Design

Built with an all-steel welded frame, the machine offers strong durability and stability under heavy-duty use. The detachable design enables easy cleaning and maintenance, allowing operators to access internal components quickly and safely.

4. Safety & Dust Control

Equipped with motor overload protection and an electric interlock system, the crusher ensures safe operation at all times. The dust separation system effectively reduces airborne particles, maintaining a cleaner and healthier working environment.

5. Ideal for Industrial Applications

Designed for high-volume production, this crusher is perfect for recycling and processing plastic sheets, profiles, and wood-plastic materials. Its reliable design and versatile operation make it suitable for continuous industrial use.

Technical Parameter of the heavy plate/sheet crusher

| الطراز | OSJ600 | OSJ800 | OSJ800 | OSJ1000 | OSJ1200 | OSJ1500 | OSJ2000 |

|---|---|---|---|---|---|---|---|

| الطاقة (KW) | 22/30 | 37/45/55 | 37/45/55 | 55/75/90 | 75/90/110 | 75/90/110 | 150 |

| الطاقة الهيدروليكية (KW) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| رقم الشفرة(PCS) | 2×3 | 2×3 | 2×5 | 2×5 | 2×5 | 2×5 | 4×7 |

| رقم الشفرة(PCS) | 2 | 4 | 4 | 4 | 4 | 4 | 8 |

| حجم مدخل التغذية (مم) | 600×400 | 800×500 | 800×650 | 1000×800 | 1200×800 | 1500×800 | 2000×800 |

| طول عمود الدوران (مم) | 600 | 800 | 800 | 1000 | 1200 | 1500 | 2000 |

| الوزن (كجم) | 1760 | 3150 | 3150 | 3850 | 4580 | 6580 | 10500 |

Application of The heavy plate/sheet crusher

مصانع إعادة تدوير البلاستيك: Efficiently crushes large plastic sheets and profiles for secondary processing.

Wood-Plastic Composite Manufacturing: Handles wood-plastic boards and profiles, reducing waste volume for reuse.

Industrial Scrap Processing: Ideal for high-volume material recovery in factories and workshops.

Custom Material Preparation: Prepares long or bulky materials for further processing in molding or extrusion lines.

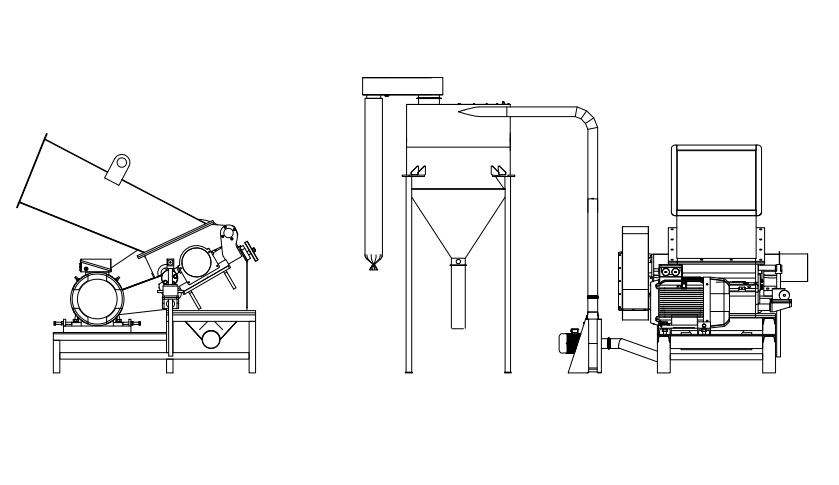

Structure of the heavy plate/sheet crusher

الأسئلة الشائعة

What types of materials can this plate/sheet crusher handle?

It can process plastics, plastic profiles, wood-plastic boards, and similar composite materials.

Can this plate/sheet crusher handle long materials without jamming?

Yes, the automatic gripping rotor ensures long pieces are fed smoothly without blockage.

Is this machine suitable for high-volume recycling?

Absolutely. Its efficient crushing chamber is designed for large quantities and bulky materials.