Introduction au broyeur de plastique à ouverture latérale

Le broyeur de matières plastiques à ouverture latérale permet une alimentation à double mode : il peut alimenter les matériaux en lots par l'orifice d'alimentation conventionnel ou réaliser une alimentation précise par le tube d'alimentation latéral. Les deux modes peuvent être commutés de manière flexible, pour s'adapter aux différentes formes de matériaux et aux exigences opérationnelles, et le fonctionnement est pratique et efficace.

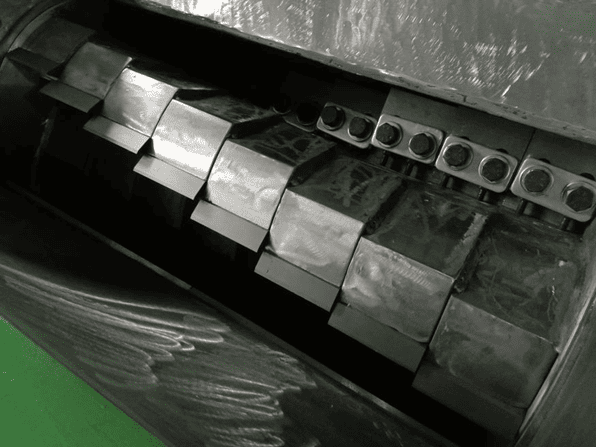

Caractéristiques du broyeur de plastique à ouverture latérale

1. Alimentation bimode

Il prend en charge à la fois l'alimentation par lots et l'alimentation précise par un tube latéral, ce qui permet aux opérateurs de passer facilement d'un mode à l'autre. Cette flexibilité permet de répondre efficacement aux différents besoins de production sans interrompre le flux de travail.

2. Fonctionnement souple

Il s'adapte à différentes formes, tailles et volumes de matériaux, ce qui lui permet de répondre à diverses exigences industrielles. Le broyeur peut traiter les matériaux de manière cohérente, quelle que soit leur longueur ou leur épaisseur.

3. Rendement élevé

La conception optimisée de la chambre de broyage empêche le blocage des matériaux, ce qui permet un fonctionnement continu. Il conserve des performances stables même en cas d'utilisation intensive, ce qui réduit les temps d'arrêt et améliore la productivité.

4. Conception conviviale

La combinaison d'un tube d'alimentation latéral et d'une trémie conventionnelle simplifie le chargement des matériaux, améliorant ainsi le flux de travail et réduisant les efforts de main-d'œuvre. Les opérateurs peuvent charger les matériaux avec un minimum d'ajustement ou de supervision.

Paramètres techniques du broyeur de plastique à ouverture latérale

| Modèle | PP400 | PP500 | PP600 | PP700 | PP800 | PP960 | PP1000 |

|---|---|---|---|---|---|---|---|

| Puissance (HP) | 10 | 15/20 | 20/30 | 20/30 | 30/40/50 | 50/60/75 | 50/60 |

| Lame numérotée (PCS) [Déménagement] | 12 | 15 | 18 | 21 | 24 | 27 | 30 |

| Lame numérotée (PCS) [Fixe] | 2 | 2 | 2 | 2 | 4 | 4 | 4 |

| Chambre de broyage (MM) | 410×230 | 515×295 | 615×320 | 715×320 | 825×470 | 960×600 | 1025×470 |

| Capacité de broyage (KG/H) | 200-250 | 300-350 | 350-450 | 400-500 | 450-600 | 600-700 | 600-800 |

| Dimensions L (MM) | 1200 | 1435 | 1580 | 1610 | 1800 | 2000 | 1800 |

| Dimensions W (MM) | 850 | 1100 | 1100 | 1210 | 2000 | 2200 | 1800 |

| Dimensions H (MM) | 1340 | 1550 | 1650 | 1740 | 2340 | 2340 | 2700 |

| Poids (KG) | 500 | 900 | 1100 | 1100 | 2000 | 2500 | 3000 |

Application du broyeur de plastique à ouverture latérale

- Recyclage du plastique et des profilés

Idéal pour les usines de recyclage, le broyeur de plastique à ouverture latérale traite efficacement les plastiques, les profilés en plastique et les déchets composites. Le double mode d'alimentation permet un contrôle précis de l'entrée, optimisant ainsi le débit. - Fabrication de composites bois-plastique (WPC)

Dans la production de WPC, le broyeur traite des planches et des profilés de différentes tailles. Son alimentation flexible assure un traitement en douceur des pièces longues ou irrégulières, réduisant ainsi les déchets et préparant les matériaux à la réutilisation. - Traitement de la ferraille industrielle

Les usines produisant des déchets de tailles diverses peuvent compter sur le broyeur de plastique à ouverture latérale pour la récupération de gros volumes. L'alimentation à double mode assure un fonctionnement continu et des temps d'arrêt minimes. - Prétraitement pour l'extrusion et le moulage

Le broyeur prépare les matières premières pour le moulage ou l'extrusion en réduisant les grandes feuilles ou les profils à des tailles gérables. Une alimentation latérale précise permet de maintenir un flux de matériaux constant pour la production en aval. - Atelier et manutention sur mesure

Les petits et moyens ateliers bénéficient des options d'alimentation flexibles du concasseur. Les opérateurs peuvent choisir une alimentation par lots ou précise en fonction du type de matériau et des besoins de traitement.

FAQ

Quels matériaux le broyeur de plastique à ouverture latérale peut-il traiter ?

Elle transforme des matières plastiques, des profilés en plastique, des panneaux composites bois-plastique et des matériaux similaires.

Comment fonctionne l'alimentation bimode ?

Les matériaux peuvent être acheminés par lots via la trémie principale ou avec précision via le tube d'alimentation latéral. Le passage d'un mode à l'autre est rapide et pratique.

Le broyeur de plastique à ouverture latérale peut-il traiter des matériaux longs ou irréguliers sans se bloquer ?

Oui, le broyeur de plastique à ouverture latérale est conçu pour une alimentation et un fonctionnement en douceur, même avec des pièces longues ou encombrantes.