Ⅰ. 工業用チラーの作動原理

産業用チラーの基本機能 プロセス流体から熱を奪い、大気中に放出することである。 冷凍サイクルは四つの主要なステップから成る:蒸発、圧縮、凝縮、膨張。最初のステップとして、低温・低圧の冷媒が蒸発器内に導入され、そこで冷却対象のプロセス流体からエネルギーを吸収する(自らのエネルギーを放出する)。これにより気化が起こる。気化した冷媒は圧縮機へ流れ込み、そこで高温・高圧の気体へと変換される。.

次の段階では、この新たに加熱・加圧された冷媒ガスが凝縮器に流入し、そこで熱を放出して冷却され液体に変化する。最後に、この液体冷媒は膨張弁を通過する。膨張弁は圧力と温度を低下させる役割を担い、その後、減圧・低温状態で再び蒸発器に流入し、新たな冷凍サイクルを開始する。.

II. 産業用チラーの主要構成要素

産業用水冷却器の効率的な稼働は、精密に設計された中核部品に依存しています。これらの部品は装置の性能を決定するだけでなく、信頼性と保守コストにも影響を与えます。以下に産業用水冷却器の主要部品とその機能をいくつか示します。.

1. 蒸発器

蒸発器は、プロセス流体から十分な熱を吸収して冷媒を気化させることで冷凍サイクルを開始する構成部品である。その設計と使用材料は冷却効率に直接影響する。一般的な蒸発器の種類には、シェルアンドチューブ式蒸発器とプレート式蒸発器がある。シェルアンドチューブ式蒸発器は構造が単純でメンテナンスが容易なため、中規模の工業用水冷却器に推奨される場合がある。 プレート式蒸発器はより高い熱交換効率を実現しますが、構造が比較的複雑で、維持コストも高くなります。予算制約内で特定の産業用途に最適なタイプを選択することが、その選定基準となります。.

2. コンプレッサー

コンプレッサーは工業用水冷装置の動力中核として機能し、冷媒循環を駆動する。その性能は冷凍サイクルの効率とエネルギー消費に直接影響する。一般的なコンプレッサーの種類には、スクリューコンプレッサー、ピストンコンプレッサー、遠心式コンプレッサーがある。.

- スクリューコンプレッサーはコンパクト設計と滑らかな運転特性を備えており、中型から大型の産業用水冷却器に適しています。.

- ピストン式コンプレッサーは高い圧縮効率を提供する一方で、比較的複雑な構造と高いメンテナンスコストを特徴とする。.

遠心式コンプレッサーは大型産業用水チラーに最適です。効率的で静粛性に優れています。コンプレッサーを選定する際には、必要な冷却能力、装置のサイズ、運転コストを考慮する必要があります。.

3. コンデンサー

凝縮器は高温高圧の冷媒ガスを冷却し液体へと変化させると同時に、熱を環境に放出する。その性能は冷凍サイクルの効率とエネルギー消費に直接影響する。一般的な凝縮器の種類には空冷式と水冷式がある。.

空冷式凝縮器は空気を冷却媒体として使用する。構造が簡素で保守が容易だが、冷却効率が比較的低いため、主に小型産業用チラーに用いられる。水冷式凝縮器は運転時に水を冷却媒体として適用するため、高い冷却効率を提供する一方、安定した水の供給を必要とする。この特性から、大型産業用水チラーに最適である。選択すべき凝縮器のタイプは、具体的な産業用途と冷却条件によって決まる。.

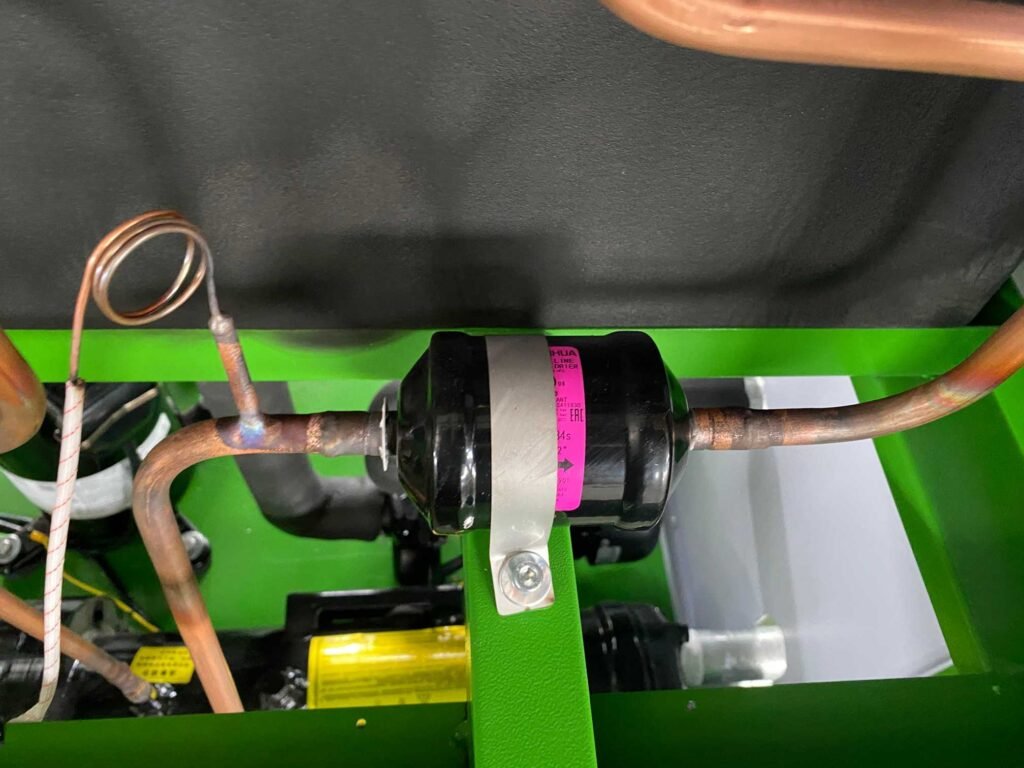

4. 膨張弁

膨張弁は冷凍サイクルにおける重要な制御部品である。冷媒の流れと圧力を調節し、冷媒が蒸発器に入る前に適切な状態に達することを保証する。膨張弁の性能は冷凍サイクルの効率と安定性に直接影響する。.

一般的な膨張弁の種類には、手動式と自動式があります。手動式膨張弁は手動調整が必要で、操作は比較的煩雑ですがコストは低くなります。自動式膨張弁は冷凍サイクルの実際の要求に基づいて自動調整が可能で、操作は便利ですがコストが高くなります。適切な膨張弁の種類を選択するには、特定の産業用途と運用要件を考慮する必要があります。.

III. 産業用チラーの種類

工業用水チラーには複数の種類があり、それぞれが異なる用途に最適化されています。各種工業用水チラーとその用途を理解することで、ユーザーは自身のニーズに適した機器をより適切に選択できます。.

1. 空冷式産業用チラー

空冷式産業用チラーは空気を冷却媒体として利用するため、スペースが限られている場所や冷却水源がない場所に適しています。このタイプは構造がシンプルで設置が容易、メンテナンスコストも低くなっています。ただし、空気の冷却効率が比較的低いため、空冷式チラーの冷凍能力には一定の限界があります。そのため、小規模な産業用途や冷却需要が控えめな環境で一般的に使用されます。 例えば、小規模な電子機器製造工場や実験室では、空冷式チラーが装置を効果的に冷却し、正常な動作を保証します。.

2. 水冷式産業用チラー

水冷式産業用チラーは水を冷却媒体として利用し、主に大規模な産業施設に導入される。高い冷却効率を発揮し、大規模な工業生産の冷却需要を満たすことが可能である。水冷式チラーの凝縮器は安定した給水が必要であるため、機器選定時には冷却水の供給・排水システムを慎重に検討する必要がある。.

水冷式チラーはメンテナンスがより必要です。スケールや錆などの問題を防ぐため、冷却水システムを定期的に点検・保守しなければなりません。しかし冷却性能が非常に優れているため、多くの大規模産業で採用されています。例えば化学製造では、反応器の冷却に使用されます。これにより化学反応が最適な温度で行われ、結果として生産効率が向上し、製品の品質も向上します。.

3. 吸収式冷凍機

吸収式冷凍機は、熱エネルギーを利用して冷凍サイクルを駆動する特殊な産業用水冷装置である。電力供給が極めて限られている状況や、大量の廃熱を回収可能な場合に最適である。冷却吸収ユニットは、標準的な圧縮式ユニットのように吸収剤と冷媒の化学反応を利用しないが、一般的な吸収剤としては臭化リチウムとアンモニアが用いられる。 吸収式冷却装置の最大の利点は、電力消費が極めて少ない点にあり、エネルギー供給が制約される状況下で特異的な利便性を発揮します。ただし、冷凍効率が低く、設備コストが高いことに加え、定期的なメンテナンスや添加剤の継続的な補充が必要となります。このため、その用途は主に太陽熱冷凍システムや廃熱利用設備など、特定の産業用途に限定されてきました。.

IV.結論

産業用冷却装置は現代の工業生産において重要な役割を担っています。その動作原理は複雑で、用途も多岐にわたります。動作メカニズム、主要部品、種類、メンテナンス方法を理解することで、この設備の適切な選択と運用が可能となり、あらゆる産業環境における冷却ニーズに対応できます。 食品加工、化学製造、電子機器生産において、工業用水冷却装置は効率的かつ安定して稼働します。これらは円滑な産業運営を支えています。技術の進歩に伴い、工業用水チラーはさらに優れた性能と効率を発揮するようになり、産業生産にさらなる利便性と利益をもたらすでしょう。.