Industrielle Kältemaschinen play a vital role in modern industrial production. It is this machine that provides steady cooling for various industrial equipment to ensure an efficient production process. However, the performance and life of the machines depend largely on their maintenance. The paper will discuss industrial chiller maintenance standards, providing detailed guidelines and tips on maintenance to help you keep your equipment in optimal condition.

I. The Importance of Industrial Chiller Maintenance

Industrial water chillers are complex systems that require meticulous maintenance to operate efficiently. Regular maintenance not only extends the lifespan of the equipment but also improves its efficiency, reduces downtime, and lowers operating costs.

Industrial chiller maintenance is not only about fending off equipment failures but also about keeping the production process going and making sure it runs smoothly. In many industrial uses, when the chiller goes down, it can stop production and cause big money losses. That’s why regular maintenance is key to ensuring the equipment runs well for a long time.

II. Key Maintenance Practices for Industrial Chiller

1. The Value of Preventive Maintenance

Preventive maintenance is the heart of any industrial chiller maintenance program. Regular checks on refrigerant pressure, cooling water quality, and compressor operating status easily spot potential problems ahead of time. For example, cleaning that, if neglected, would allow reduced net 15%-20% heat exchange efficiency to build up is better done regularly since it takes less effort than corrective cleaning when the equipment breaks down. Apart from increasing the life of the equipment by reducing the failure rate, preventive maintenance will increase production due to reduced unplanned downtimes and hence will improve economic benefits.

2. Specific preventive maintenance measures include

Regular checks on the pressure of the refrigerant because the main cooling medium of industrial water chillers is refrigerant, and its pressure stability will ensure efficiency in cooling for the equipment. If pressure is within normal range, then no losses of cooling efficiency due to leaks and shortages of refrigerant can be attained.

Watch the Cooling Water Quality: Cooling water has much to do with chiller performance. Regular testing of cooling water for pH, hardness, and content of impurities will keep scale and microorganism buildup away. Not only does scale reduce heat exchange efficiency, but it can also create blockages in the pipes carrying cooling water, which runs through the equipment.

Look at the Compressor: The chiller’s work and life mostly depend on the compressor. Often check its running facts like current, voltage, and heat to find possible problems and stop downtime caused by compressor failure.

3. Cleaning and Decontamination

Condenser and Evaporator Cleaning: Regularly clean the condenser and evaporator fins to remove dust and dirt. This dirt reduces heat exchange efficiency and leads to reduced system operating efficiency. Quarterly cleaning is recommended.

System Decontamination: Regularly clean the refrigerant and water systems to prevent microbial growth and corrosion. These contaminants not only reduce system efficiency but can also cause equipment damage.

4. Filter Replacement

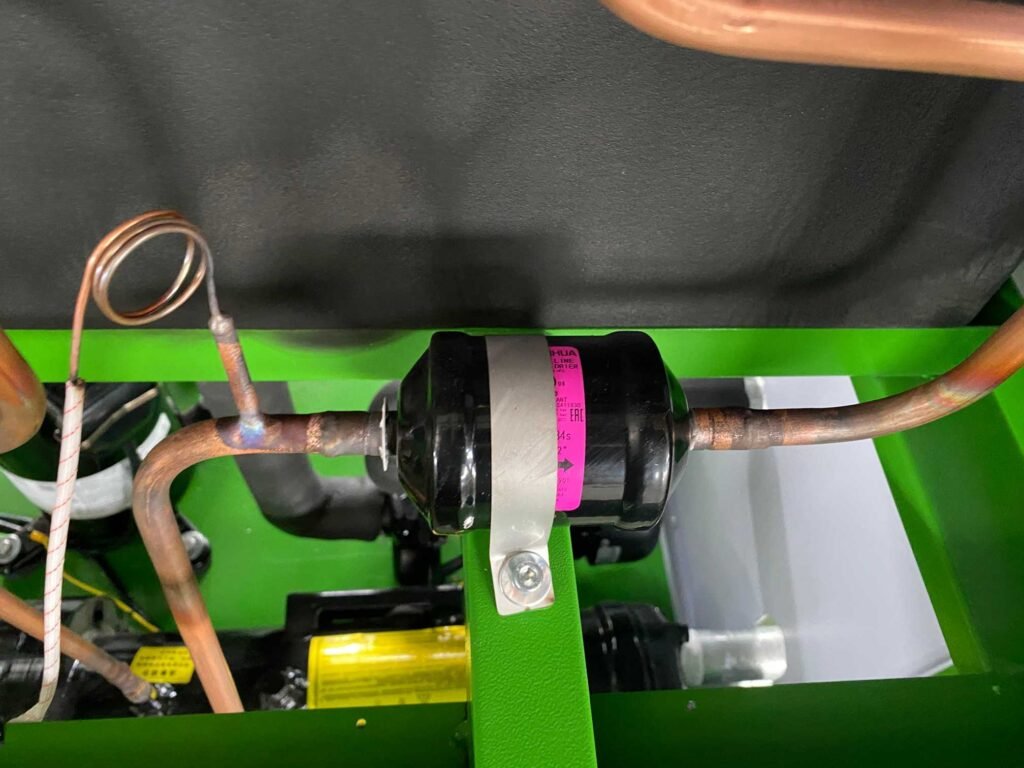

Regular Filter Replacement: Filters play a critical role in maintaining the purity of refrigerant and cooling water. Regularly replacing or cleaning filters prevents system contamination and ensures efficient operation. Filter replacement is recommended every six months, depending on equipment usage.

Checking Filter Condition: When replacing filters, inspect the condition of the filters to ensure they are not damaged or clogged. If any filter is found to be damaged, replace it immediately.

5. Lubrication and Component Inspection

Lubricating Components: Regularly check and replace lubricants to ensure that all moving parts are properly lubricated. Insufficient lubrication can cause component wear and reduce equipment life.

Check Component Condition: Inspect components such as belts, seals, and gaskets for wear and tear, and replace damaged parts promptly. Damage to these components may cause system leaks or reduced operating efficiency.

6. Refrigerant Management

Check the refrigerant level and pressure regularly to ensure adequate refrigerant and no leaks. Low refrigerant can make the system inefficient and even cause damage to the compressor. Follow all environmental regulations when handling refrigerant. Not only does it make the system less efficient, but its effects on the environment are quite devastating.

III. Advanced Maintenance Techniques for Industrial Chillers

In addition to basic maintenance practices, there are several advanced maintenance techniques that can further improve the performance and lifespan of your industrial chiller:

1. Energy Efficiency Audits

Carry Out Regular Energy Efficiency Audits: System inefficiencies are easily spotted with the help of regular energy efficiency audits. Recommendations on improvements that will significantly minimize energy consumption include operating cost savings.

Reset chiller settings: Items to be adjusted after carrying out an energy audit on a system include refrigerant quantity, cooling water flow, and evaporator temperature.

2. Smart Monitoring System

Install an Intelligent Observation System: Intelligent observation systems watch the chiller’s working condition in real time and give detailed data on performance. They can also spot anomalies right away and send warnings before issues become serious.

Predictive Upkeep: Predictive upkeep with the help of intelligent observation systems enables proactive upkeep planning, thus lessening unplanned stoppage time. By looking at the running data of the machine, spots where it might fail can be found out earlier and fixed proactively, or parts replaced before they break down.

3. Personnel Training

Regularly train maintenance personnel to ensure they are familiar with industrial chiller maintenance standards and operating procedures. Professional training enhances maintenance personnel’s skills and ensures efficient equipment maintenance.

4. Seasonal Adjustment

Chiller operating parameters may require adjustment according to the prevailing season. For instance, in high summer temperatures, increase the cooling water flow and refrigerant charge so that heat can be effectively dispersed. In winter, make sure that provisions are made against freezing the cooling water system, which might later damage the equipment. This is done with the use of antifreeze or the simple draining of the cooling water system during downtime.

Ⅳ. Common Issues and Solutions for Industrial Chiller Maintenance

Although regular maintenance can significantly improve the performance and lifespan of industrial chillers, some common problems can still occur in actual operation. The following are some common problems and their solutions:

1. Refrigerant Leakage

Refrigerant leakages are common from industrial chillers. This can not only reduce efficiency but can also lead to damage to the compressor. To avoid getting into such problems, it is better to regularly check the level and pressure of refrigerant in a system so that leaks can be detected and repaired on time. When dealing with refrigerants, strictly follow environmental rules and ensure safe operation.

2. Condenser and Evaporator Blockage

Dust, dirt, and scale most commonly foul the fins of the condenser and evaporator, greatly lowering their efficiency in heat exchange. This problem can be solved by allowing a detailed cleaning process for the condenser and evaporator on a quarterly basis with the use of proper tools and detergents for cleaning. The cleaning water system may also have filters installed in it to decrease the amount of impurities entering the condenser and evaporator, so that this extends further the period between cleanings. Regularly check fin condition; prompt attention to any buildup of scale will keep the exchange efficient.

3. Motor Overload

Motor overload can cause the motor to overheat and even damage it. Motor overload is often caused by insufficient refrigerant, insufficient cooling water flow, or abnormal system pressure. To avoid these problems, regularly check the motor operating current to ensure it is operating within the rated current range. Also, inspect the refrigerant and cooling water systems to ensure sufficient refrigerant and normal cooling water flow. If motor overload is detected, promptly investigate and correct any related issues, such as refrigerant leaks or cooling water system blockages.

4. Cooling Water System Problems

Scale and microbial growth in the cooling water system can reduce cooling water flow and hurt system efficiency. Scale lowers heat exchange efficiency, and microbial growth can clog the cooling water system. To solve these problems, regularly clean the cooling water system with special cleaning agents and equipment to remove scale and impurities. Adding anti-scaling agents and biocides to the cooling water can prevent scale and microbial growth effectively.

VI. Schlussfolgerung

Care for industrial water chillers is very critical to their efficiency and lifespan. The maintenance tasks include cleaning and replacing parts, checking for leaks, replacing filters, lubricating, and good refrigerant management, among others. These steps may improve efficiency as well as reliability. Other advanced techniques that can further improve performance while reducing costs include energy audits, intelligent monitoring, staff training, and seasonal adjustments.